Table Of Content

Heat pumps can have mini-split systems with or without ductwork. Conventional air-source heat pumps need ducts to move air through the home. Ductless systems circulate refrigerant through small conduit lines from outdoor compressors to indoor blower units. Adding a vent to existing ductwork costs $250 to $500, depending on the home layout. Adding additional HVAC air vents lowers the overall system efficiency and raises utility bills.

$270 – $500 cost per duct run (replacement)

You’ll be able to tell which of your vents are supply vents because you can feel air coming from them. Some supply vents have adjustable slats, allowing you to adjust the airflow according to your preference. Replacing ductwork takes 1 to 2 days on average or up to 4 days for larger homes or complex projects. Installation time depends on the home’s size, age, number of HVAC units, duct type, and crew size.

How Do You Balance Return Air Flow?

Very cold, hot, and humid climates benefit most from duct insulation. Duct Armor costs $5,000 to $30,000, depending on the ductwork size, type, condition, accessibility, and prep work. Installers spray this sealant inside ducts to create a ¼” thick rubberized duct liner that completely coats, seals, and restores old ductwork. Mobile home ductwork replacement costs $1,000 to $3,300 on average, depending on the mobile home size, duct material, and accessibility. Ductwork in mobile homes is typically under the floor with the insulation, which makes replacement difficult.

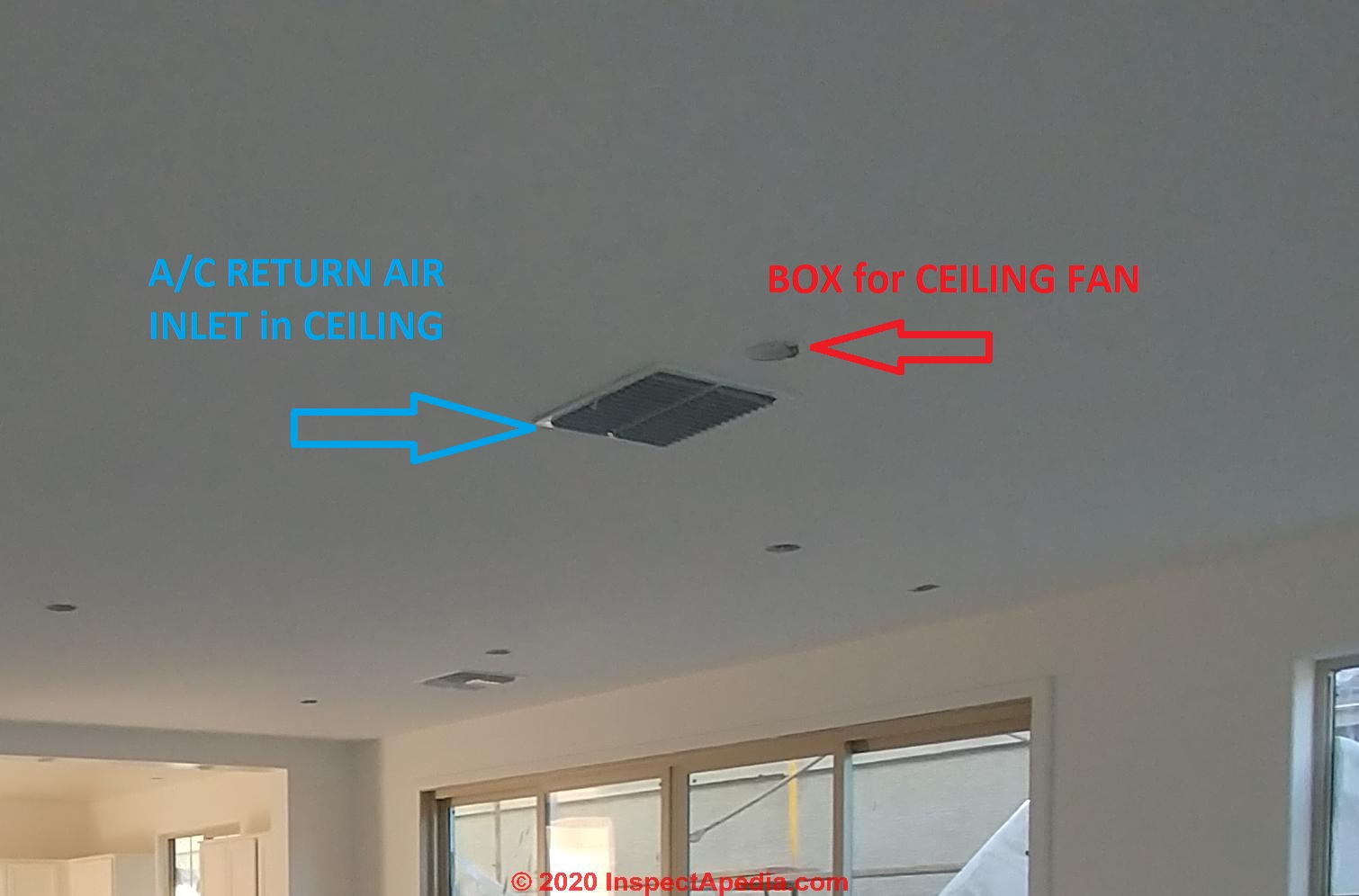

Where should return ducts be located?

Cleaning your return air duct doesn’t have to take too much time, money, or energy, and it can greatly increase your air quality and your HVAC system’s functionality. Keeping your return air ductwork clean is a great way to ensure that your HVAC system works as it should and helps promote good air quality. If you or someone in your family has severe allergies, keeping your ductwork clean is even more important.

Can you use flex ducts in a crawl space?

This WWII bunker used a fake air vent to return grenade to sender - Military Times

This WWII bunker used a fake air vent to return grenade to sender.

Posted: Wed, 31 Aug 2022 07:00:00 GMT [source]

Typically, central air conditioners are sized based on how many cooling tons your house needs. The duct is typically hidden, but you can usually see where it begins by looking for vent grates in the wall, ceiling, or floor. Often, these vents are in a hallway or ceiling because they’re most effective in these locations. If you are thinking about installing the ductwork as a DIY project, keep in mind it is a large and involved project.

The R indicates that the fitting is Rectangular, and the 3 identifies the fitting as an elbow. Note that the cross-sectional areas at sections 0 and 1 are not equal. Otherwise, the elbow would be a Common fitting such as CR3-6. At converging transitions, velocity pressure increases in the direction of airflow, and absolute total and absolute static pressures decrease. I hope this guide has shed some light on the ins and outs of return air vents and how crucial they are for your home’s comfort and your HVAC system’s efficiency. Additionally, by facilitating air circulation, return air vents help reduce moisture levels in your home, decreasing the risk of mold and mildew growth.

How Return Air Vents Affect Indoor Air Quality

Pattern Cut is the leading manufacturer and supplier of decorative laser cut wood grilles, moldings, and panels. We love to give your home a refreshing new look with our beautifully created laser cut patterns for a timelessly classic look that never goes out of fashion. Air Conditioning Supply and Return Air Grille Covers will look like works of art on your walls and ceilings.

Most cities require this to ensure a licensed professional will be responsible for the project. Costs vary from state to state and average between $10 to $100 but can be more. You can check out our local information page to find your city or state for information specific to HVAC installation in your area.

Return Duct Size Chart (Velocity >700 FPM)

Mechanical equipment rooms, including air-handling units, should be centrally located to centralize maintenance and operation. But, for many reasons, not all equipment rooms can be centrally located in the building. In any case, equipment should be kept together whenever possible to minimize space requirement, centralize maintenance and operation, and simplify electrical systems. All HVAC air system equipment rooms should have space for maintaining equipment and the replacement of fans, coils and other key equipment. Inlet spin may arise from many different approach conditions, and sometimes the cause is not obvious. Figure 15 shows some common duct connections that cause inlet spin.

Now, we want to select a duct size that has the capacity to carry 800 CFM. For return air ducts, the ACCA or Air Conditioning Contractors of America suggest the air velocity within the duct should not exceed 700 feet per minute (FPM) for noise control. Figure 7 shows total and static pressure changes in a fan/duct system consisting of a fan with both supply and return air ductwork. Also shown are total and static pressure gradients referenced to atmospheric pressure. Generally, duct design starts with identifying the airflow needed in each room.

Door undercuts help, but they are usually not sufficient for return airflow. A basic estimate of how much you can save by DIYing a ductwork project is based on the per hour cost of a professional HVAC specialist. Prices vary from state to state, but typically a professional installer may charge at least $50 to $55 per hour for labor and materials. A building permit costs $50 to $250 for installing new ductwork.

No comments:

Post a Comment